(Image courtesy of Wiliot.)

Imagine having a conversation with a shipment of shrimp arriving at a warehouse. The facility manager might ask: "How was your journey? Did you encounter any issues en route? How fresh are you compared to the other seafood in this shipment? How quickly should I get you onto store shelves?"

Since the 2000s, the network of everyday tech connected to the internet that collect and share data, also known as the Internet of Things (IoT), has been gathering such information from supply chains, thanks to the introduction of radio frequency identification (RFID) tags. These small tags help track products and inventory levels and enhance.

But this technology demands costly infrastructure and labor. Understaffed supply chain management often results in inefficient scanning of the tags and inaccurate assumptions. Consequently, products frequently arrive late, damaged or go missing entirely.

“We're in the 21st century, yet so much of the supply chain management still relies on limited data and guesswork," said Steve Statler, chief marketing officer at Wiliot, a tech startup specializing in the logistics industry. "The most expensive part isn’t necessarily the technology, it’s the human labor required to track products manually. A handheld scanner might cost $1,000, but it’s the person operating it that adds the real cost.”

Emerging technologies like Ambient IoT — a new version of Internet of Things devices that power themselves using energy found around them, like light or heat — combined with artificial intelligence (AI), can introduce increased visibility and efficiency to supply chain information. Together, these technologies can generate logical insights that users can access easily and quickly through AI-powered chat.

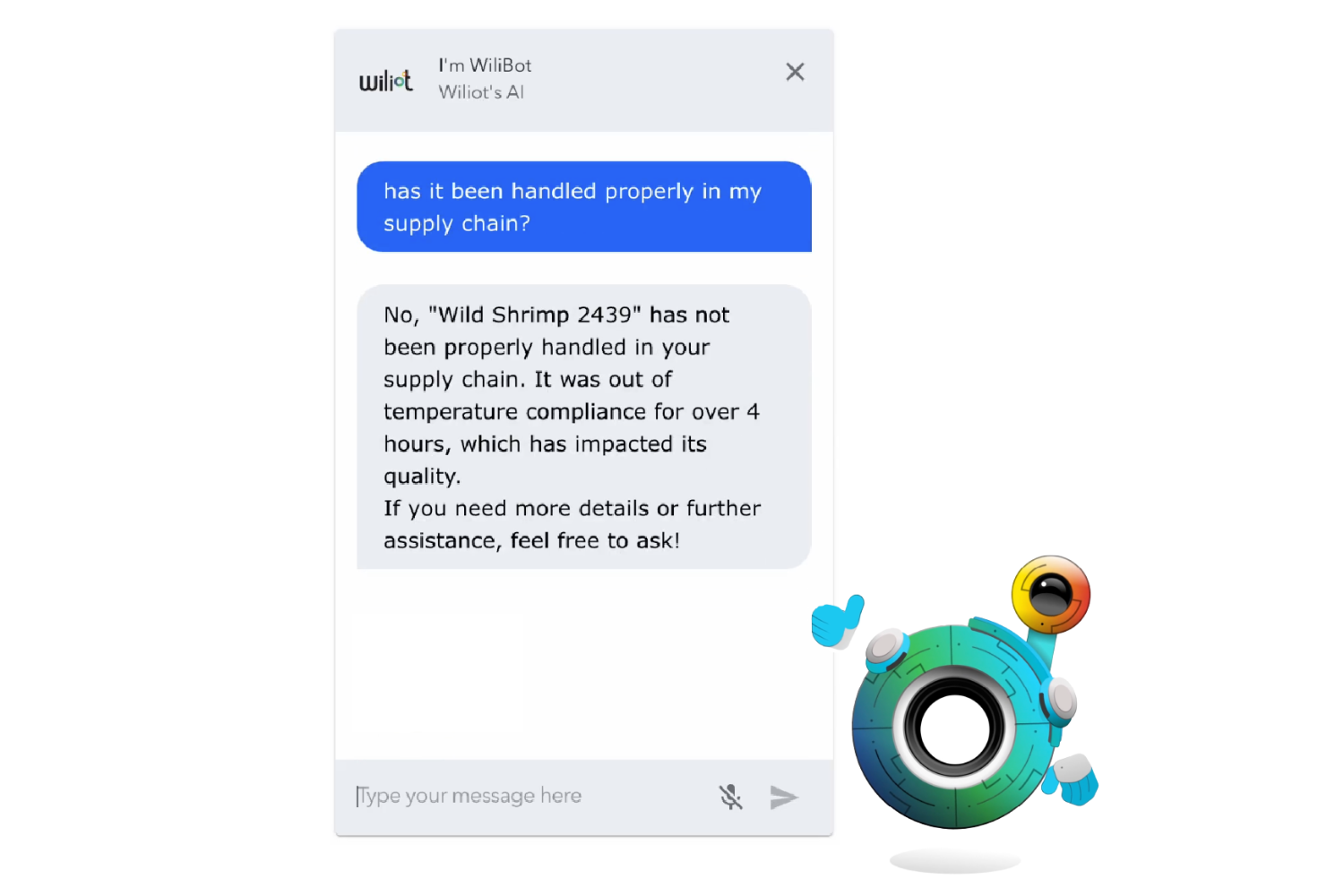

Wiliot recently developed such a solution, called WiliBot, that offers end-to-end data on the movement of goods using a combination of low-cost, battery-free Bluetooth stickers and AI.

The battery-free Bluetooth stickers are the size of a postage stamp. They can be stuck on the goods at any point in time, and from then on, they constantly broadcast their location. These tags, unlike RFID or barcodes, don’t rely on manual scanning. They harness energy from radio waves around them to power themselves and send continuous data on the item’s location and condition.

"Instead of relying on somebody to scan the item, which can be missed, we get a real-time, constant feed of where everything is at all times," said Eric Casavant, director of technical marketing at Wiliot. “This means tracking stuff, like food temperatures or where packages are, is now much cheaper and works everywhere, without needing expensive new equipment.”

The term coined to describe this future of supply chain management is "omniscient retail."

The challenge with such visibility is the sheer volume of data generated. “If you could see everything, everywhere, all the time, you'd go crazy,” Statler said. “That's where AI comes in. AI processes these enormous data streams and converts them into actionable insights.”

All of the information gathered by the stickers can be assessed by scanning the sticker and asking the AI a question like, “Was this product handled properly during shipping?” That enables everyone, from CEOs to store managers, to make decisions in real time. By turning raw data into clear recommendations, businesses can reduce waste, improve on-shelf availability and tighten their supply chains.

WiliBot does more than just track goods. It also addresses some of the broader issues facing the AI industry. “There’s a problem with the data quality AI relies on,” Statler said. “Often, we’re dealing with subjective data, incomplete or even manipulated information. But when we use Bluetooth sensors to track things like temperature and location, we're working with the ground truth — undistorted, reliable facts.”

One practical application of this technology is in food safety. From ensuring that shrimp stays within the correct temperature range to preventing shipments from being misdelivered, Wiliot’s system promises to transform how retailers manage perishables. "It's all about having accurate, real-time data, not relying on guesswork," Statler said.

This accuracy is especially crucial in industries where transparency and traceability are becoming regulatory requirements. The European Union is introducing new laws like digital product passports, for example, requiring companies to disclose the provenance and environmental impact of their products.

“Consumers want, and have the right, to know if their food was harvested responsibly or if their clothes were made using sustainable practices," Casavant said. "With Ambient IoT, we can track and verify every step of the process, from farm to shelf."

While the system is still in its infancy, it has already proven its potential with some of the world’s largest retailers and postal services. Royal Mail in the United Kingdom is the first delivery company in the world to use Wiliot’s tracking solution. The company has equipped its 850,000 wheeled containers with Wiliot's Bluetooth tags, enabling them to transmit live data on location, humidity, and temperature as they move across the country.

Wiliot's system is scalable across industries and is already gaining traction in healthcare and pharmaceuticals, where product safety and traceability are paramount. The technology can even monitor the carbon footprint of individual products, helping businesses meet sustainability goals and comply with environmental regulations.

While the future of supply chain management is more than just reducing costs, “Carbon equals cost,” Casavant said. “When we help businesses reduce their carbon footprint, we’re also improving their bottom line. Real-time, actionable data about a product’s journey doesn’t just satisfy regulatory requirements, it’s an economic advantage.”

With complete transparency and actionable insights, businesses are empowered to optimize operations, reduce waste, and embrace a more sustainable future.

Abha Malpani Naismith is a writer and communications professional who works towards helping businesses grow in Dubai. She is a strong believer in the triple bottom line and keen to make a difference. She is also a new mum, trying to work out a balance between thriving at work and being a mum. In her endeavor to do that, she founded the Working Mums Club, a newsletter for mums who want to build better careers and be better mums.