(Image: Colton Duke/Unsplash)

When you think about major sources of greenhouse gas emissions, you probably think about carbon dioxide emissions resulting from energy production, or transportation. It goes without saying these are huge drivers. But you might not think about embodied emissions from the construction of the world's infrastructure.

Embodied carbon from new infrastructure is expected to be responsible for half of the global carbon footprint between now and 2050, Savina Carluccio, executive director of the International Coalition for Sustainable Infrastructure, said in a statement.

Embodied carbon is the emissions associated with the extraction, production, transport, and manufacturing of all building materials before on-site construction even begins. Before a piece of infrastructure is in use, carbon is already embodied in these building blocks.

With the built environment contributing so significantly to greenhouse gas emissions, accurately accounting for embodied carbon is increasingly urgent. Yet, it is historically painstaking to do and often overlooked.

Infrastructure engineering software company Bentley Systems announced its Carbon Analysis tool earlier this month at the company’s annual Year In Infrastructure conference. The tool aims to make carbon accounting much easier, much faster, and importantly, even assist engineers in mitigating the carbon footprint of their infrastructure projects.

TriplePundit was invited to attend the event, where we spoke with Chris Bradshaw, Bentley Systems’ chief sustainability officer, about the tool and how it fits in with the company’s sustainability goals.

Bentley Systems’ software is used globally to design, operate and maintain all kinds of infrastructure projects — anything from roads, bridges, wind farms, dams and any type of building. As part of the design process, engineers build virtual models of their projects using the software and, increasingly important within the industry, create digital twins. A digital twin is an accurate virtual rendering of something in the physical world.

Digital twins are distinguished from decades-old computer-aided design or simulation software because they are linked to numerous data sources throughout the lifecycle of design, build and operational phases. So the model is continually updated in real-time. This allows for far greater accuracy, letting designers and engineers modify the digital twin to predict how any changes they make will manifest in the real world.

Digital twins can incorporate artificial intelligence tools, as well, to further enhance their power as engineers test among different design scenarios. Important too, they provide a holistic representation, rather than keeping information in separate silos.

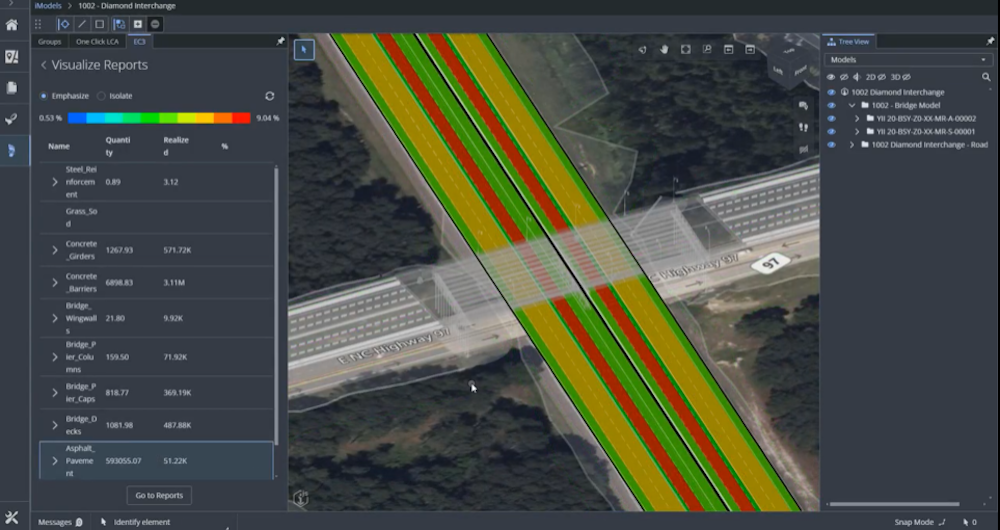

Bentley Systems’ new Carbon Analysis tool dovetails with the company’s artificial intelligence-powered digital twin software, iTwin Experience. The pair simplifies carbon reporting by allowing engineers to compile carbon reports concurrently with the design process. This improves upon the traditional approach, where reporting is typically a laborious additional task that might take weeks or months to compile.

With the new Carbon Analysis tool, engineers can quickly map their project materials data to a third-party carbon calculator of their choice. And because the tool makes this simple to do, engineers can compare material and design choices for whatever they are building to see how different options increase or decrease embodied carbon in real-time.

“Sustainable development occurs when you balance perfectly the environment, the economic and the social impact,” Bradshaw said. “We see, fundamentally, a digital twin being the mechanism to help do that.”

Bradshaw used an example from his hometown to explain how this balancing act might look.

“We have a bridge, which goes over a small body of water,” Bradshaw said. “It is made of wood, it’s historical and people love it. But the thing’s falling apart. The county said they’re going to replace it with concrete and steel, and the community was up in arms saying, ‘No, we want another wooden bridge.’ So now you are in a conversation about what you are trading off. With a digital twin, you can scenario-optioneer to your heart’s content.”

Let’s say the county uses Bentley Systems’ software. It could create a digital twin of each bridge option. One in concrete and steel, and another from wood. Using the new tool, it could very quickly determine the embodied carbon of either option, while simultaneously representing aesthetic and functional requirements.

And since the tool creates a three-dimensional heat map of where concentrations of embodied carbon are found in a design, the visual rendering points to possible opportunities to mitigate embodied carbon. Three-dimensional visualization provides a secondary benefit, as well.

“It allows non-engineers to participate in the conversation, too,” Bradshaw said. “As you can visualize in a way that everyone gets to understand.”

Of course, what actually gets built is subject to a range of factors, so the Carbon Analysis tool won’t force owners of a project to reduce the carbon footprint. And easy carbon reporting doesn’t mean owners of infrastructure projects will necessarily make carbon mitigation a focus. But as Bradshaw said, “The good news is, infrastructure owners are getting more savvy to it.”

The company is incorporating the new tool into its digital twin product at no additional cost.

“We took that path because we feel very strongly that this is something that the world needs to do,” Bradshaw said. “So we don’t want to create a price barrier to our users in being able to do these calculations.”

Perhaps in the future, though, engineers won’t have a choice. Bradshaw said he thinks infrastructure engineers will increasingly have to properly account for embodied carbon.

“All infrastructure in the world is either owned by governments or regulated by governments,” Bradshaw said. “Because of that, governments can accelerate the evolution to more sustainability and resilience through regulations or contract requirements. So far, not enough, but I think this will change on a year-to-year basis.”

Whatever the regulatory framework looks like going forward, there are benefits to using digital tools, Mark Coates, the company’s international director of public policy and advocacy, told 3p at the event.

He built upon the age-old maxim: measure twice, cut once. Instead, “Build digitally, two, three, four times. You make fewer mistakes, increase the chance of being on time and under budget, and you use less carbon because of reduced mistakes while promoting best practices.”

Editor's Note: Travel and accommodations to Vancouver, Canada, were provided by Bentley Systems. Neither the author nor TriplePundit were required to write about the experience.

Phil Covington holds an MBA in Sustainable Management from Presidio Graduate School. In the past, he spent 16 years in the freight transportation and logistics industry. Today, Phil's writing focuses on transportation, forestry, technology and matters of sustainability in business.