(Image: Maxim Hopman/Unsplash)

Despite huge gains in electric vehicle (EV) battery performance, where 300-plus miles of driving range is becoming the norm, some limitations with batteries still impact the user experience. EVs perform best in temperate conditions, which means drivers may suffer a performance penalty if they operate their vehicles in extreme heat or cold.

In extremely cold temperatures, the range tends to diminish. It can be reduced by around 12 percent at 20 degrees Fahrenheit, according to a 2019 report by the American Automobile Association. And recharging in freezing conditions takes longer, too. At the other extreme, repeated operation of EVs at very high temperatures can accelerate battery aging and lead to a diminished life for vehicle batteries.

Japanese technology company, Asahi Kasei, claims to have found a solution to these temperature-related problems with a breakthrough high ionic conductive electrolyte for lithium-ion battery cells. Triple Pundit recently spoke with Mike Franchy, director of North American mobility, sales and marketing at Asahi Kasei, who explained the company’s innovation in detail.

How the new electrolyte works

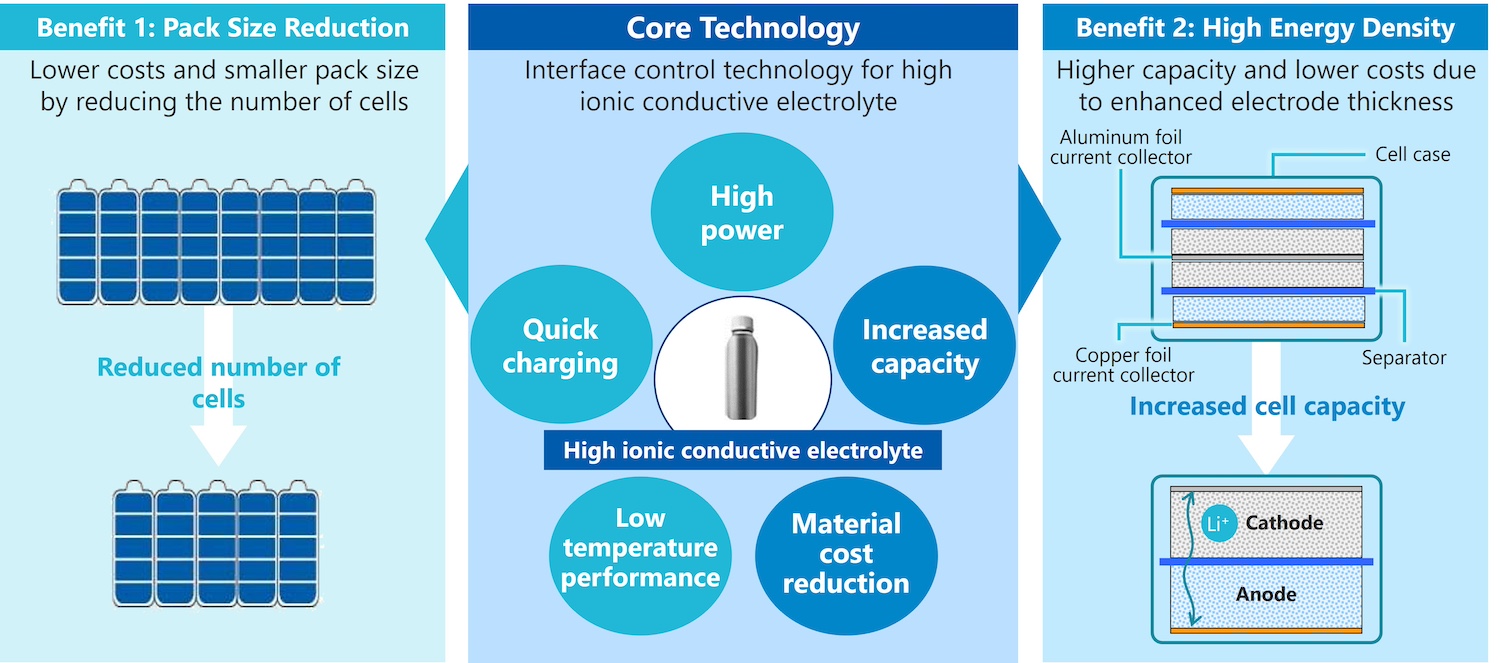

The movement of lithium ions from one side of the battery to the other is what creates a charge, and the electrolyte is a solid or fluid chemical that allows them to move.

“Ionic conductivity is the measure of a material’s ability to conduct electric current using the movement of lithium ions through the electrolyte,” Franchy said. “Our product allows the ions to move faster and more efficiently, thereby improving the performance of the battery.”

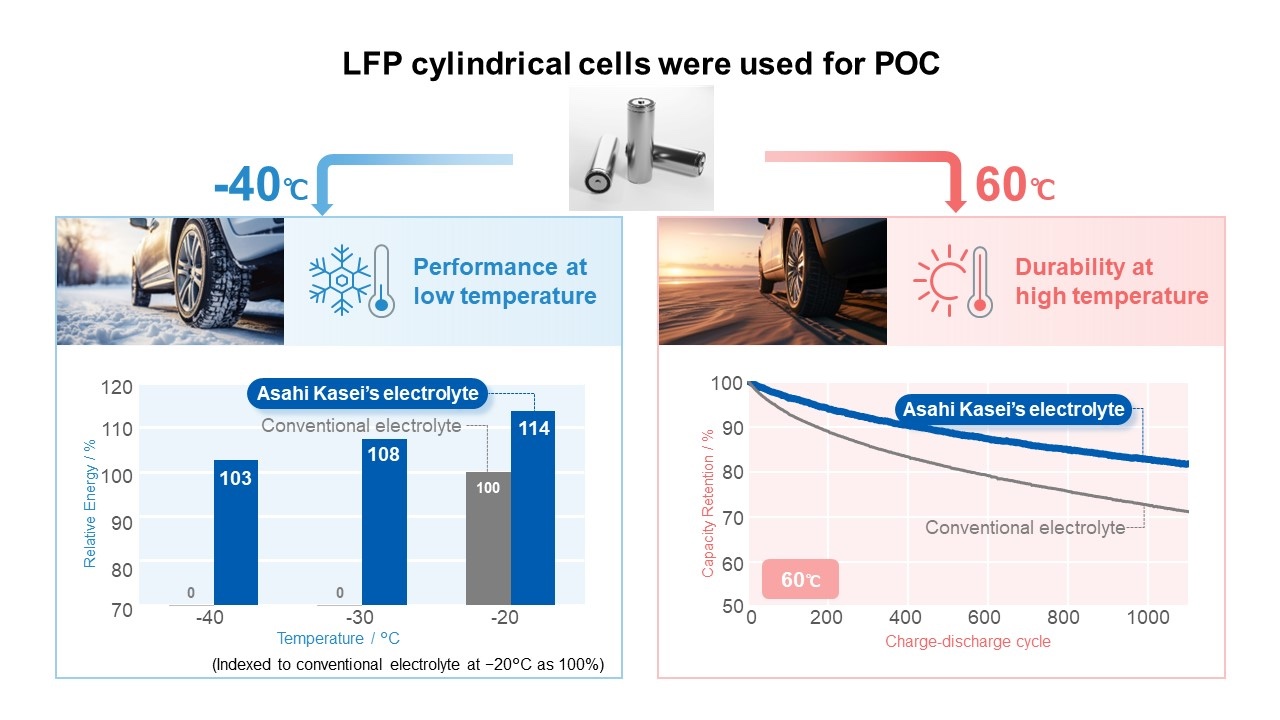

In a proof-of-concept test with a battery cell manufacturer, Asahi Kasei’s new electrolyte achieved high power performance at -40 degrees Fahrenheit, according to the company. Toward the other extreme, at 140 degrees Fahrenheit, the life of the battery doubled compared to typical batteries.

As well as these findings, Franchy suggested another significant benefit. “The time it takes to charge [a battery] from 10 to 80 percent [of its full charge] can be reduced up to 50 percent, depending on the exact cell design,” he said.

The key to these marked performance improvements comes down to a particular electrolyte ingredient: the chemical compound acetonitrile. It offers a superior ability to store electrical energy coupled with low viscosity, meaning it flows easily with little friction.

Asahi Kasei started experimenting with acetonitrile in 2010. Until now, it didn’t work well with graphite, an important battery material that causes acetonitrile to decompose. The company’s breakthrough is a unique formulation that prevents that from happening.

Keeping up with the ever-evolving battery industry

The development of this new electrolyte coincides with ever-evolving lithium-ion battery designs. The proof-of-concept of Asahi Kasei’s electrolyte was done in collaboration with a battery maker using cylindrical lithium-iron phosphate batteries (LFPs), Franchy said. This variant of lithium-ion batteries, named after the materials used to make it, is becoming increasingly attractive for vehicles because it is cheaper. LFPs avoid nickel, manganese and cobalt, which are all expensive elements used in the most common type of lithium-ion battery.

Asahi Kasei’s electrolyte will be suitable for both battery types, but “[Manufacturers] such as Tesla and Ford are using LFP batteries to reduce the cost of vehicles,” Franchy said. “So developing a product that can contribute to increased range and faster charging will benefit both [manufacturers] and consumers.”

LFP batteries are increasingly important in the energy storage sector, too, which means improving the performance and long-term durability of these batteries will also be a benefit in storing renewable energy.

Asahi Kasei expects commercialization of its electrolyte to begin in 2025. The manufacturing process isn't different than current state-of-the-art liquid electrolytes, so licensees will have a low implementation hurdle, Franchy said.

Nonetheless, using the company’s electrolyte is not quite at the plug-and-play stage. Optimizing the new electrolyte for the batteries that are most commonly used in higher-performance and longer-range vehicles is still at the research and development stage, Franchy said.

And the electrolyte probably doesn’t make sense to use in all lithium-ion batteries. Franchy explained that conventional electrolytes are better for consumer electronics devices since they don’t require high power demand or have to withstand operation under extreme temperatures. Consumer electronics manufacturers would likely choose to avoid the inevitable costs of changing electrolytes.

But by targeting increasingly important LFP batteries and testing the electrolyte to commercial standards, the company believes there is great potential to increase demand for lithium-ion batteries for EVs and energy storage systems in cold and tropical regions alike. The battery industry is in constant flux, and while solid-state batteries (which do not use electrolytes) are often cited as the future of EV technology, that future is not yet here.

Besides, there is still a lot of room for improvement within current battery design, Franchy said. And he believes Asahi Kasei’s product meets this moment. "This electrolyte can be applied to various applications that serve a wide range of markets right away.”

Phil Covington holds an MBA in Sustainable Management from Presidio Graduate School. In the past, he spent 16 years in the freight transportation and logistics industry. Today, Phil's writing focuses on transportation, forestry, technology and matters of sustainability in business.