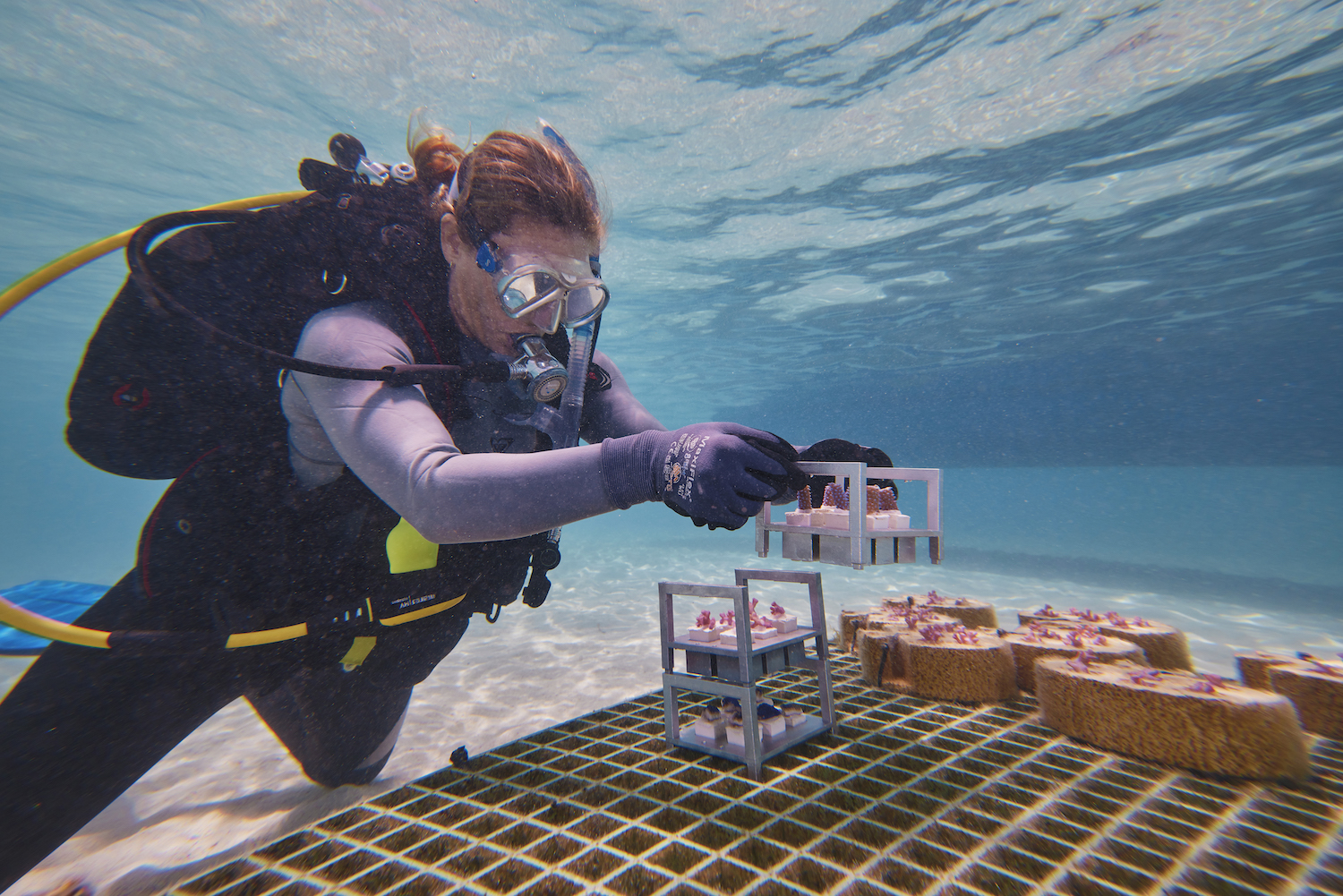

Coral biologist Taryn Foster, founder of Coral Maker, dives near Abrolhos Islands in Western Australia.

Coral reefs are considered to be the most biodiverse ecosystems on the planet. They provide societies around the world with $375 billion in ecosystem services each year, but they’re in trouble.

As of this year, the world has already lost half of its coral reefs and is on track to lose up to 90 percent by 2050, even if global warming is capped at 1.5 degrees Celsius. While governments and NGOs around the world are making policies and enacting programs to stop the demise of coral reefs, one company is turning to artificial intelligence (AI) and robotics.

Coral Maker, founded by coral biologist Taryn Foster, manufactures and deploys premade coral skeletons seeded with coral fragments. The use of premade coral skeletons significantly reduces the number of years corals take to reach their mature, adult size.

Coral Maker’s goal is to quickly scale up in order to restore 250 acres of coral reefs annually. And it's utilizing the robotics and engineering expertise of design software giant Autodesk to help make that happen.

“We are always seeking new ways of engaging with innovators and entrepreneurs. They push our thinking,” said Rick Rundell, senior director of research programs at Autodesk Research. “Coral Maker first joined us through a program at our technology center that allows people to do their own technology work. Dr. Taryn Foster collaborated with our researchers working in robotics and AI.”

The first project that Foster and the Autodesk Research team collaborated on was automating the placement of seed coral into a frame or “skeleton.” Then, Foster worked with a different team to design and manufacture the coral skeletons utilizing recycled construction materials. By providing underwater skeletons for the coral to inhabit, they can more quickly grow to maturity and propagate themselves.

Coral Maker can now manufacture 10,000 coral skeletons per day, and each skeleton holds six to eight coral fragments. The manufacturing equipment is deployed at coral reef restoration sites in order to reduce shipping and transportation emissions. Foster hopes to deliver tens of millions of coral fragments to restoration sites annually.

“The global risk is that the reefs will die faster than they can reseed,” Rundell said. “Coral Maker is seeding reefs in areas that will be more suitable for reefs in the long term. They are moving them to places where temperatures will be more suitable as the oceans warm.”

While millions of hectares of coral reefs are currently at risk of degradation, bleaching or die-offs, traditional reef restoration projects using manual methods restore less than one hectare per year. To protect and restore reefs at scale, restoration must advance quickly — which is why Coral Maker utilizes automation, robotics and AI.

“One of the things that is so challenging when you’re dealing with big, global problems like coral reef degradation is that it’s not always clear as to what one person can do,” Rundell said. “We know we need to cool the planet, but that is difficult. It is inspiring to our researchers and employees to be involved with a group like Coral Maker which is biting off a big, challenging problem in a way that seems like it could really work. They can help make it successful. That’s exciting for us.”

Images courtesy of Coral Maker and Autodesk Research

Mary Riddle is the director of sustainability consulting services for Obata. As a former farmer and farm educator, she is passionate about regenerative agriculture and sustainable food systems. She is currently based in Florence, Italy.